Release time:2022-11-14 Number of views :253

The YTCT Hydraulic Breaker hammer is a construction equipment that is used for the demolition of a structure and breaking rocks into smaller sizes.

It is a front attachment on excavator ,could use for any brand excavator from weight 0.5ton to 70 ton It applies high pressure from its small canister which has pressurized hydraulic oil stored in it.

They are much more powerful than other hand-held hammers and its force is varied based on the force of piston strokes and its size.

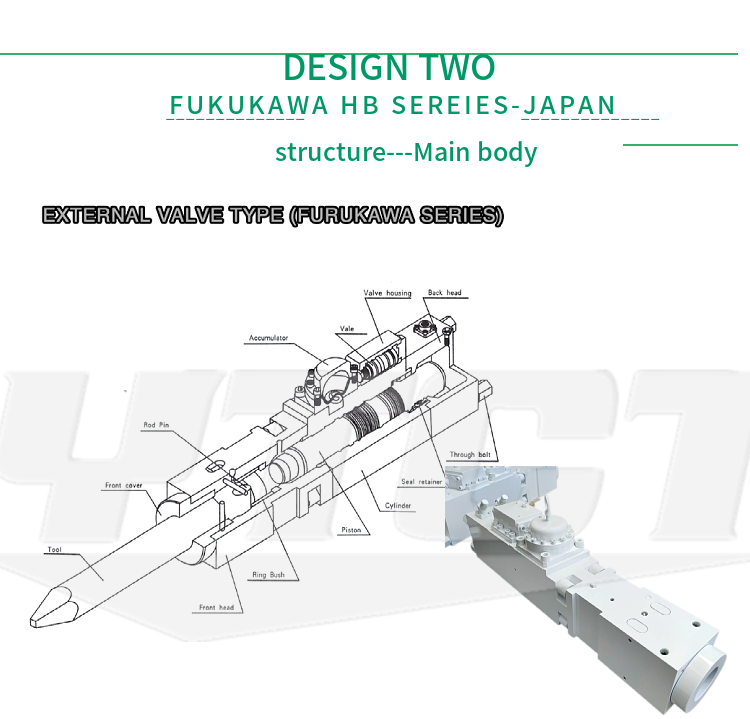

The hydraulic hammer is of two types namely – inner valve type and outer valve type

our factory could manufactuer these two model inner valve type and outer valve type toghther.

Working principle of breaking hammer:

1. Backhaul motion

The hydraulic oil enters cavity 1 and cavity 8 through the high-pressure oil pipe: the valve core is pressed at the bottom dead center by the oil pressure; The piston moves upward toward the air chamber 5. At this time, the 4 chambers are connected with the 7 chambers through the four round holes on the valve core, and the oil returns through the reversing valve.

2. Piston movement reversing

When the piston moves to the position shown in the figure, high-pressure oil enters chamber 6 through chamber 2. At this time, chambers 6 and 8 of the reversing valve are full of high-pressure oil with equal pressure. Due to the different area of the shaft shoulder, the valve core moves up.

3. Stroking motion

When the valve core is raised to the point where the round hole is connected with chamber 8, the high-pressure oil enters chamber 4 through the reversing valve. The shaft shoulder with different area produces a pressure difference on the two pistons. With the nitrogen pressure and its own gravity, the pistons move downward at an accelerated speed.

4. Strike process

After the striking process, the piston hits the drill rod. At this time, the middle part of the piston reaches cavity 2, causing cavity 6 to drain high pressure oil through cavity 2 and cavity. Since one cavity 8 is directly connected with high pressure, the spool moves down, and the round hole is connected with cavity 7 again, completing a cycle.

The working principle of the breaking hammer can also be simply understood as: hydraulic oil inlet kinetic energy+upper accumulator kinetic energy push the cylinder rod up to compress the nitrogen chamber, push the reversing valve to switch the direction after reaching the highest point, and hydraulic oil inlet kinetic energy+nitrogen compression kinetic energy push the cylinder rod down quickly to knock the drill rod to complete the breaking work.